- October 21, 2025

- by umspcs

- Blog, Latest Notifications, News & Updates

- 34 Views

- 0 Comments

In the world of industry, screws and other fasteners may at times resemble simple parts that tend to be underestimated. However, the dependability of these seemingly uncomplicated parts plays a crucial role in an abundance of applications, from electronics and furniture to vehicles and buildings. In light of this, the Indian government has implemented the BIS certification for Cross Recessed Screws Quality Control Order, 2024, which will subject these fasteners to regulatory examination by the Bureau of Indian Standards (BIS).

According to the Order, some “cross-recessed screws” used in India, whether they are imported or made domestically, must meet particular Indian Standards and be licensed to use the BIS Standard Mark.

The QCO’s main provisions, technical and regulatory ramifications, enforcement schedule, and compliance requirements for producers, importers, and distributors are all covered in this article. For clarification, a list of often asked questions is also included.

Brief Background

- In accordance with Section 16 of the BIS Act, 2016, the Central Government may, following consultation with BIS, issue a Quality Control Order (QCO), requiring compliance with certain Indian Standards. One such order is the Cross Recessed Screws QCO.

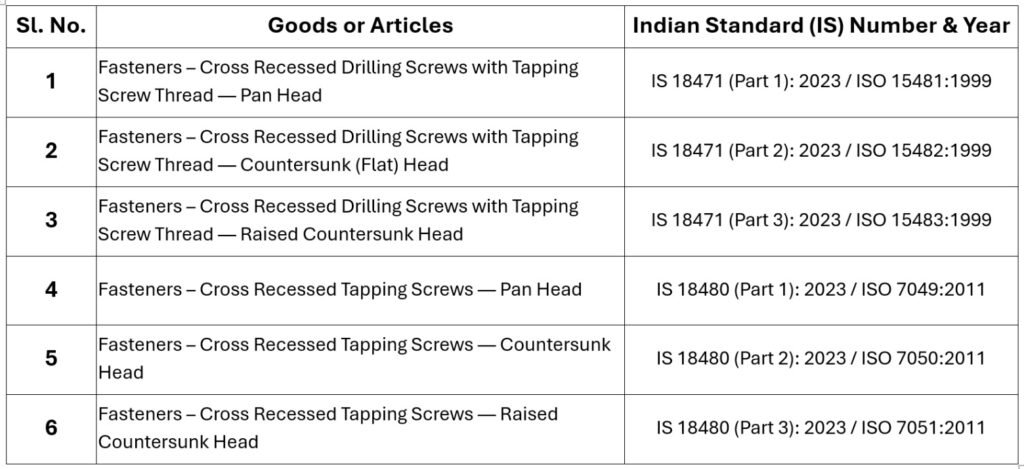

- The formal announcement, called the “BIS certification for Cross Recessed Screws QCO, 2024”, stipulates that products or items included in its Table must meet the Indian Standards indicated and be authorized by BIS to use the Standard Mark.

- A number of compliance-consulting and news platforms have noted that fasteners, particularly screw categories, are becoming more and more subject to QCO-mandated conformance.

To put it briefly, this QCO is a part of a larger movement in India to regulate the quality of important industrial inputs as opposed to just key final items.

Covered Products & Scope

Important Duties & Technical Needs

The following requirements must be met by producers, importers, and distributors of the covered screws:

1. Indian Standards Compliance

- The screws should comply with all technical requirements for the concerned IS standard (e.g., IS 18471:2023 series) in size, mechanical, materials, finish, tolerance, thread quality, and others.

- Deviations or low-quality lots will not be eligible for the BIS mark requirements and may be subject to fines or market ban.

2. Standard Mark & BIS Licensing

- In accordance with Scheme I of Schedule II of the BIS Conformity Assessment Regulations, 2018, an applicant needs to acquire a license from BIS.

- Only products with the Standard Mark and license information can be lawfully imported or marketed for the Indian market after they have been approved (subject to exemptions).

3. Dates of Effectiveness & Postponed Effects on MSMEs

- Six months after it is published in the Gazette for General Enterprises, the Order becomes operative.

4. Penalties for Violations

- The BIS Act of 2016 imposes penalties on anyone who violates the terms of this order.

- Products that don’t comply may be seized, prohibited from sale, and have their licenses canceled.

5. Exemption from Exports

- Products or items intended solely for export are exempt, which means the mark is not required in those situations.

All these must be followed to get BIS approval process for Indian manufacturers.

Chronology and Transition

The implementation is staggered in due to the magnitude of the adjustment for importers and manufacturers:

- The Order’s general enforcement date is 18 March 2025 for big and medium-sized businesses, and it was likely issued in September 2024 (for example, S.O. 4099(E) dated 17 September 2024).

- According to extension orders, enforcement is postponed for small and micro businesses until later dates (for instance, November 1, 2025), or even later for micro units.

- Manufacturers should approach this as “by early 2025 – mandatory” from a practical standpoint, albeit smaller businesses might benefit.

These deadlines offer a window for planning BIS compliance, but companies run the risk of not meeting them.

Effects & Industry Consequences

1. Safety Standards India & Quality Control

- Failures of components, assembly problems, structural concerns, or warranty claims may result from screws that do not fulfill mechanical specifications (such as thread depth, hardness, torsional strength, and finish). Baseline reliability is increased via mandatory conformance.

2. Imports & Domestic Production

- In order to comply with BIS standard mark requirements for screws

- ,domestic producers will need to make investments in testing, documentation, and perhaps tooling or process upgrades.

- Additionally, imported screws will need to comply (unless they are just intended for export) and will need to bear the BIS license for screw manufacturers or mark, which will increase the hurdles to mass importation of subpar screws.

3. Cost & Supply Chain Aspects

- The cost of upgrading BIS Product Certification India for Cross Recessed Screws and testing may go up (lab fees, license, audits). These expenses might be transferred downstream.

- Unorganized businesses or smaller importers may find it difficult to comply and run the danger of being shut out.

4. A Competitive Edge

- Early compliance gives businesses a reputational advantage; being “BIS certified” is often seen as a sign of excellence.

- Businesses who don’t comply risk being banned, delisted, or facing criticism from customers who demand certified screws.

5. Domestic vs. Export Market

- Although screws for export exclusively are excluded, companies that sell or import domestically must abide by the rules or risk being barred. Production and labeling must be clearly segregated.

Roadmap for Compliance: Action Items

This is a useful checklist that importers or manufacturers can use:

- Determine which screw models (pan head, countersunk head, raised countersunk, tapping thread, etc.) are covered by IS 18471/18480/7483/7485 in accordance with the QCO 2024 by mapping your product inventory.

- Acquire the pertinent Indian Standards. Acquire copies of the IS standards (such as IS 18471 (Part 1/2/3):2023 etc.) mentioned in the table. These define threads, dimensions, mechanical qualities, and finishes.

- Internal audit and gap analysis. Examine current test, manufacturing, and process data in comparison to the standard standards.

- Determine the non-conformities. In order to test screws for the necessary characteristics (hardness, tensile strength, driveability, corrosion, thread quality, etc.), collaborate with labs that have been accredited by the NABL or BIS.

- Submit a BIS license application under Scheme I. Create factory layouts, papers, quality management system information, test report samples, etc.

- Update labeling & packaging. After a license is obtained, screws need to have the Standard Mark, IS number, type identification, batch/lot number, and license number in accordance with BIS regulations.

- Educate employees and interact with purchasers. Make sure the QCO is known to the supply-chain partners (importers, distributors, and OEMs) so that certified screws may be used for redirected sourcing.

- Keeping test reports, batch records, quality records, and complaints logs available for BIS surveillance is the eighth step in maintaining records and market surveillance preparation.

- Keep an eye on official updates. Later, new screw kinds, extensions, modifications, or head styles may be added. Stay vigilant.

- Separate export stock if exempt. If an exemption claim is made, ring-fence screws intended for export should be clearly marked so as to prevent mixing with domestic-market stock.

This is how to get BIS certification for cross-recessed screws.

Question and Answer

According to a rule issued by the Indian government under the BIS Act, certain cross-recessed drilling screws with tapping screw threads (pan head, countersunk head, etc.) must meet specific Indian Standards and display the BIS Standard Mark under license when being imported or sold in India.

It takes effect for both large and general businesses six months after the date of publication. Nine months for small businesses and twelve months for microbusinesses following publication. For instance, March 2025 is one of the stated effective dates for larger units.

Products such as “Fasteners – Cross Recessed Drilling Screws with Tapping Screw Thread Part 1 Pan Head (IS 18471 Part 1)” and related Parts 2, 3, and others are included in the table. Series IS 18480 tapping screws (Parts 1, 2, 3) are also included.

The QCO would not be complied with. After the enforcement date, it is illegal to sell or import such screws for the domestic market, and the BIS Act may impose fines.

No. Like local screws, imported screws sold in India must adhere to regulations. But according to the Order, screws intended only for export are excluded.

Indeed. According to the MSME definition, microbusinesses may have twelve months, whereas small businesses may have nine months. The provisos of the Order expressly permit for this prolongation.

Wrapping Up

For the Indian fastener industry, the Cross Recessed Screws (Quality Control) Order, 2024 is a major regulatory step. To improve the quality and dependability of crucial fastening components, the government requires compliance with Indian Standards (such IS 18471 and IS 18480) and the BIS Standard Mark.

Despite their modest cost, fasteners have a significant impact on the integrity of the finished product, thus manufacturers, importers, OEMs, and downstream users in a variety of industries should pay attention to this regulation.

Early adopters will safeguard their supply chains and obtain a competitive advantage, even though compliance may necessitate investments in testing, documentation, quality control, and BIS certification for screws and fasteners certification. Delays put businesses at risk of liability, supply chain exclusion, prohibitions, and regulatory disruption.

Now is the moment for companies that use cross-recessed screws in their manufacturing, importing, supplying, or assembling processes to take action: map product lines, work with labs, apply for a license, change packaging, check suppliers, and remain ahead of the compliance curve.

UMSPCS is among the very best BIS certification consultants in India. Contact us now to get yours.