BIS-FMCS Certification for Foreign Manufacturers

Is one of your objectives to have your products certified under the BIS Foreign Manufacturers Certification Scheme (FMCS)?

If so, you are at the perfect spot. UMS Product Compliance Services Pvt. Ltd. (UMSPCS) is the right partner for foreign manufacturers to go through the BIS-FMCS certification process smoothly from the very first step to the last one, including standard identification, testing, factory inspection, documentation, licence grant, and post-certification compliance.

Why BIS-FMCS Certification Is Necessary

India has turned out to be one of the most rapidly growing economies globally and a very attractive place for manufacturing and selling consumer goods. The trendsetting global brands like Philips, Tata, Johnson & Johnson, and many more are either already manufacturing or selling their products in India, whereas a huge number of foreign companies are plotting out their investments here.

To keep consumers safe and ensure product quality, the Government of India has introduced mandatory product standards that are regulated by the Bureau of Indian Standards (BIS).

According to BIS-FMCS (Scheme-II), foreign manufacturers are required to obtain BIS certification prior to selling or importing products for which notification has been made in India. Products cannot be offered to Indian consumers if they do not meet these compliance requirements.

Scope of BIS-FMCS

- The scope of the FMCS program is limited to foreign manufacturers only.

- Factory inspections are required at manufacturing locations overseas.

- The program covers hundreds of products that have been notified for mandatory certification by BIS.

- Certification permits the use of the BIS Standard Mark (ISI Mark).

What UMSPCS Does

UMSPCS is the lead enterprise ensuring:

- Correct Indian Standard (IS) identification

- Coordination with laboratories recognized by BIS

- Complete documentation & application management

- Preparation for the audit of foreign factories

- Liaison with BIS until the license is granted

- Compliance with the regulations & timely renewal of the license

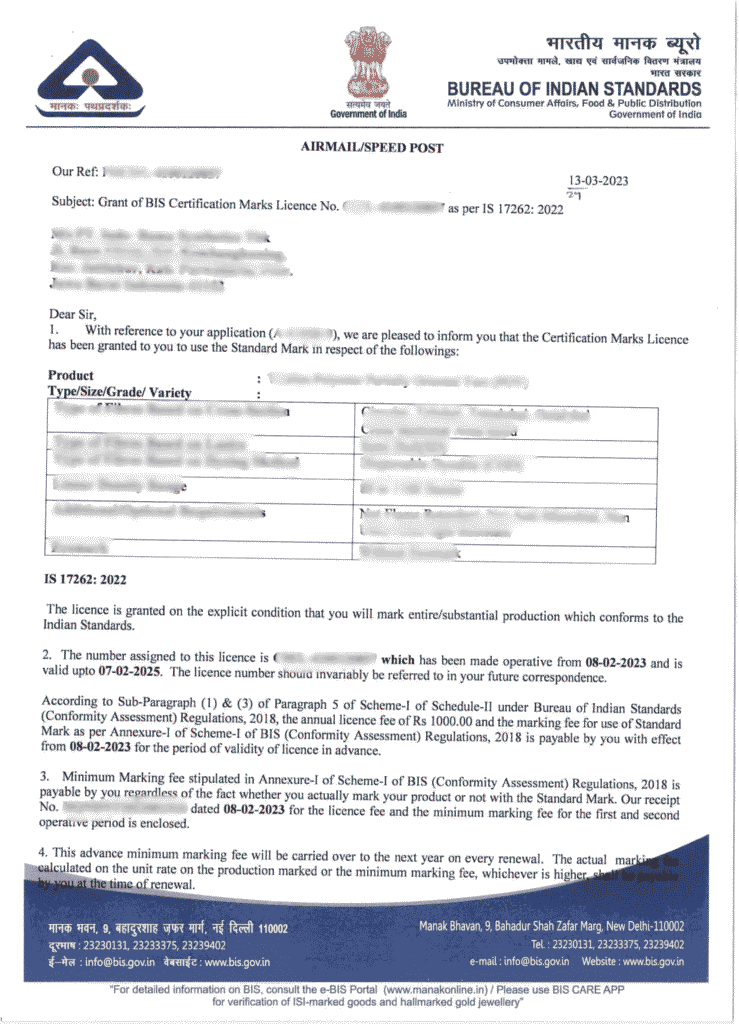

Sample of a Grant License for ISI Marks

List of Documents Required for ISI (BIS) Certification

General Documents (Indian Manufacturers)

- Basic information of the manufacturing unit and product category

- Test report issued by a laboratory recognized by BIS / accredited by NABL as per the applicable Indian standard

- Proof of manufacturing unit address (ownership/lease deed, utility bill, etc.)

- Trademark registration certificate, if the brand name is registered

- Manufacturing licence /statutory approvals, where applicable

- Product drawings /design schematics

- Installed manufacturing capacity

- Details of the raw materials used

- List and specifications of manufacturing machinery

- Factory layout plan (production, testing, storage areas)

- Manufacturing process flow chart

- Type and method of product packaging

- List of the in-house test equipment with calibration details

- Details of quality control personnel

- Method of disposal of non-conforming /sub-standard products

- Factory organizational chart

- Location map of the factory

Specific Requirements for Foreign Manufacturers (FMCS / Scheme-II)

- Authorized Indian Representative (AIR) appointment letter

- Identity and address proof of AIR

- Overseas factory documents (layout, machinery, QC setup)

- Undertaking and affidavits as per BIS format

- Consent for BIS inspection of foreign manufacturing unit

Costing and Timeline

Kindly contact us with your product details at UMSPCS Customer Care to receive an attractive and customized quotation.

Standard Timeline

Foreign manufacturers - 5 - 6 months approx.

Registration Process

Process for Foreign Manufacturer

A BIS-ISI certificate can be obtained by following the steps below:

Application

1-Gathering of all the necessary documents

2-Document submission and application fee

3-Allocation of Application Number

4-Review of applications

Query Raised (If Any)

Notification of any missing document or Non-compliance Submission of the reply

Inspection (Audit)

The payment of the inspection/audit fee

1-Appointment of the Inspecting Officer

2-Schedule the itinerary according to availability

3-Inspection of the Manufacturing Unit to check the

4-Testing facilities for 3 man-days

Sample Testing

1-Samples taken during the manufacturing process were examined in the audit

2-Samples sealed and drawn for sending to the BIS BIS-approved laboratory

3-Test Reports received from the Laboratory to BIS (FMCD)

Grant of License

If the sample is found to be in conformity, the notice to pay licensing and marking fees is sent.

The Grant of License letter is issued.

Indemnity & PBG

The Agreement / Indemnity Bond is signed by the Authorized Indian Representative.

Performance Bank Guarantee (PBG) for USD 10,000 is submitted.

Validity and Renewal

The initial duration of the licence to use the Standard Mark (FMCS-ISI) will be no less than one year and no more than two years. Applications with the necessary fees and supporting documentation under the current licence may be submitted to extend the product variety covered by the licence.

By paying renewal costs and marking fees together with a few supporting documents, a licence may be renewed for another period of five years.

Product List

PRODUCTS UNDER BIS REGISTRATION SCHEME

Currently, there are the following products that must be registered with BIS and require BIS Registration to manufacture/Import and sell the product in the INDIAN market. For more details, click on the products listed below.